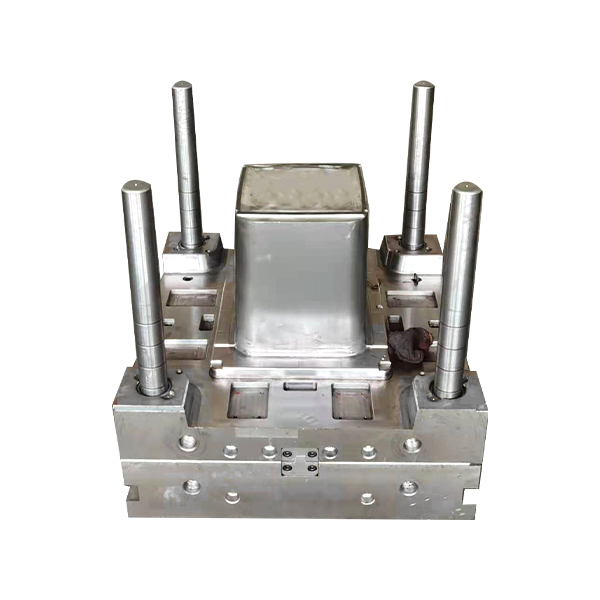

Under the dual impetus of the global plastic ban and the low-carbon goal, the market for degradable plastics is growing rapidly at a rate of over 20% annually. More and more enterprises are either using or planning to use degradable materials such as PLA, PBS, and PHA. Taking the common PLA disposable tableware mold as an example, KELONG MOULD will delve into the design essence of degradable material injection molds and provide you with a systematic solution.

Amid the upsurge of industrial transformation, a widespread pain point is plaguing many manufacturers: "Why do we always encounter various problems when producing degradable products with traditional molds?" Low yield rate, unstable dimensions, surface defects, low production efficiency... These problems are often not due to the quality of the materials themselves, but rather because traditional molds are not designed for degradable materials.

First, KELONG MOULD works closely with material suppliers when designing tableware molds to obtain the exact shrinkage rate of a specific grade of material in the customer 's injection molding process, and then conducts precise design. High-gloss corrosion-resistant steel and pre-hardened corrosion-resistant steel are preferred for steel, and the surface of the steel is strengthened.

PLA is a highly fluid material that can be used with needle valve hot runners or small-sized gates to prevent drooling and excessive pressure holding. PLA material is relatively brittle and prone to sticking to the mold. It is not easy to fall off during demolding and is likely to produce white marks or crack. We can increase the number of ejector pins (20-30% more than the traditional design) and reduce the force-bearing area of each individual ejector pin. Give priority to using push plate demolding or air-assisted demolding to achieve large-scale smooth ejection. We can also apply a Teflon coating on the surface of the mold to reduce the adhesion.

When PLA is heated, a small amount of "water vapor" is produced. If it gets trapped in the mold, it will cause defects in the product. Cologne's approach: Make fine exhaust grooves at appropriate positions, and they should be deeper than traditional exhaust grooves. This way, the products produced have a smooth surface without bubbles or scorch marks.

KELONG MOULD has served over 30 manufacturers of PLA disposable tableware. Through our collaboration, we have achieved continuous production without mold jamming, without machine stopping, and the production yield has increased from 85% to 96.5%. Today, with the irreversible trend of environmental protection, PLA disposable tableware has changed from an "option" to a "must". Choosing a set of professional molds is not about cost, but a strategic investment for you to seize market opportunities, establish quality barriers and achieve sustainable development. KELONG MOULD, with 15 years of dedication and innovation, helps you navigate the wave of green manufacturing steadily and far.

English

English Español

Español

.jpg)

.jpg)