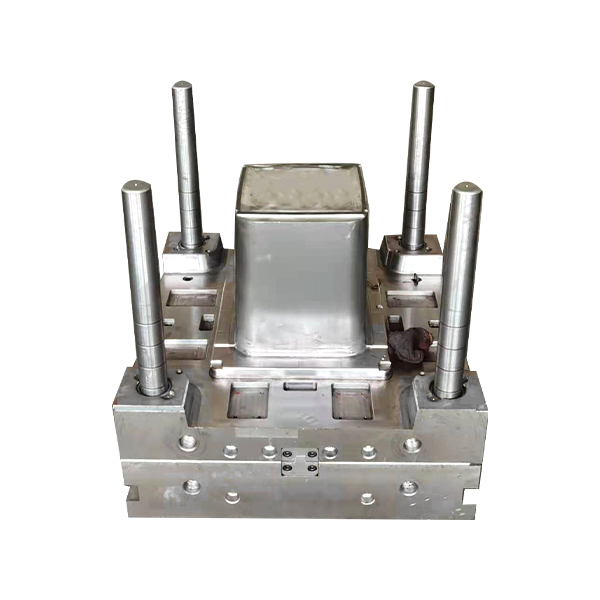

Beer boxes are common logistics turnover boxes in our daily life, and beer box molds are also one of the most frequently received molds by various mold companies. A plastic beer case, which will carry the weight of 16 to 24 bottles of beer, undergoes tens of thousands of cycles in the supply chain - transportation jolts, impacts during handling, pressure from stacking multiple layers, and cleaning and disinfection. This seemingly simple-structured product actually has very high requirements when in use, which also demands that the beer box mold have high quality.

The main body of the Kelong beer box mold is generally made of pre-hardened P20 steel, which takes into account both processability and basic wear resistance. For moving parts such as sliders and inclined tops, we use imported H13 steel and apply deep nitriding treatment, which results in higher surface hardness. This "graded steel use" strategy ensures critical service life while controlling costs.

long time in an environment ranging from -25℃ to 60℃. This means that the mold must create a solid framework through precise reinforcing ribs. A single set of molds needs to produce one million boxes, and each production cycle is compressed to 35 to 45 seconds. The efficiency of the cooling system directly determines the throughput of the production line. We adopted 3D conformal cooling technology in the thick-walled area of the box to reduce the distance between the waterway and the cavity surface, thereby increasing the cooling efficiency by 30%. A one-second cycle optimization means an increase of hundreds of thousands of cases in annual production capacity.

The underlying logic revealed by a single malfunction

Last year, during the stacking test of a set of beer case molds produced by our client, a strange phenomenon occurred: the boxes were stacked perfectly when empty, but when fully loaded with beer and piled up to the fifth layer, the overall structure was always slightly tilted. Finally, through analysis, we identified the cause: there was a 5% difference in the cooling water flow at the four corners of the mold, which led to the two corners cooling too quickly, inconsistent shrinkage, and slight deformation of the product. After identifying the cause, we not only corrected the waterway but also designed a 0.15mm pre-deformation compensation at the bottom rib position of the box. After the correction, the stacking stability of the boxes has been improved from 5 layers to 8 layers. This case validates the core logic of beer box molds: the microscopic precision determines the macroscopic load-bearing capacity.

There is not much room for innovation in the design of beer box molds. In this field, true innovation is often silent - it could be a 0.5mm offset adjustment in the waterway design, or a 2-micron thickening of the coating on the slider guide rail. These seemingly tiny figures, when accumulated, can make a beer case as stable as a mountain even when fully loaded and stacked in eight layers, and can also perfectly protect the beer after hundreds of logistics cycles. The quality of beer case molds cannot be judged by the naked eye, but it can be reflected in consumers' usage experiences.

English

English Español

Español

.jpg)

.jpg)