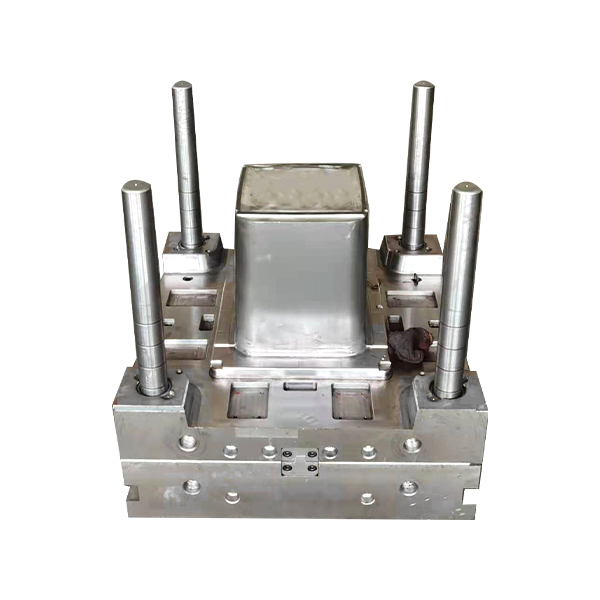

In injection molds, PET transparent product molds are the touchstone of the highest standards. Any defect will be very obvious on the product. This type of product is very prone to problems such as fogging, whitening, and water ripples. This article will take the PET storage box mold as an example, directly address the three core defects, analyze the problems from the root cause of the mold, and provide practical and effective solutions.

Firstly, the design of the cooling system directly determines the transparency, whitening/cracking, dimensional stability, and production efficiency of PET products. It can be said that an unreasonable cooling design is sufficient to ruin the top-quality steel and polishing process. The key points of the design are three: 1. Close to each other and densely arranged: The water pipes should be as close to the shape of the product as possible and arranged in several rows. 1. Do not allow the temperature difference of the mold to be large. 2. The cooling water must flow at a fast rate so as to quickly remove heat. 3. For products with complex shapes, ordinary water pipes cannot reach in. At this point, beryllium copper inserts (which absorb heat quickly) or 3D printed waterways (the water pipes can bend and follow the shape) can be used for focused cooling.

Only when the waterway design of the mold is good can PET products be transparent and bright, not deform, and the production speed be faster. This is the worthwhile part of the mold to put in effort.

PET transparent products are very prone to problems such as fogging, whitening and water ripples.

- The surface of the product is foggy

The specific phenomenon of fogging is that the surface of the product loses its crystal-like transparency, presenting a hazy white mist, and the transparency of the product decreases. For PET storage box molds, this issue is the most fatal, directly affecting the appearance of the product.

Mold cure solution: On steel, KELONG MOULD suggests using high-hardness mold steel. Steel with low hardness contains impurities such as sulfides inside. After polishing, these impurities will become tiny light scattering points, causing fogging. The polishing texture must be unidirectional and linear ground. Any "vortex-like" or "orange peel-like" texture must be reworked. Soft water or deionized water should be used as cooling water. Hard water (with high calcium and magnesium ions) will form a scale film on the surface of the high-temperature mold, resulting in uneven heat transfer and local fogging of the product.

- The product turns white

Whitening is usually the appearance of star-shaped or patchy white marks at the top pinhole, the root of the rib or the gate

Mold cure solution: For the whitening at the ejector pin, the number and diameter of the ejector pins can be increased to provide a smoother and larger ejection contact surface. Also appropriately increase the draft Angle. For transparent PET storage box molds, it is recommended that the draft Angle on each side be ≥1.5°.

If the reinforcing ribs of the product cool down too quickly, they will contract first, holding onto the raw materials that have not yet cooled, causing the root of the ribs to turn white. Ensure that the temperature difference of the mold is within a certain range through the design of the cooling system. The gate can be designed in a fan shape to increase its width. For high-end products, hot runner needle valve gates are the preferred choice

- There are ripples on the surface of the product

The patterns similar to water waves or annual rings that appear on the surface of corrugated products are the marks left by the fluctuations and stagnation during the melting of plastic.

Mold cure solution: Raise the mold temperature to the upper limit allowed by the process (usually 90-110°C). High temperature keeps plastic fluid and ensures smooth fusion, which is the effective way to eliminate ripples. Increase the diameter of the runner and the size of the gate to reduce the flow resistance and enable the plastic to move forward at a more stable speed.

For PET transparent molds, fogging, whitening and rippling are not simple issues but precise signals sent by the molds to us. KELONG's solutions always start with the honest and detailed assessment of the mold's own condition. We look forward to cooperating with you in the future.

English

English Español

Español

.jpg)

.jpg)