Kelong offers a complete design solution, providing customer support at all of a product development cycle. If you have a new idea, we will develop your ideas, exploring innovative solutions from concept sketches, all the way through to a fully engineered and marketable solution.

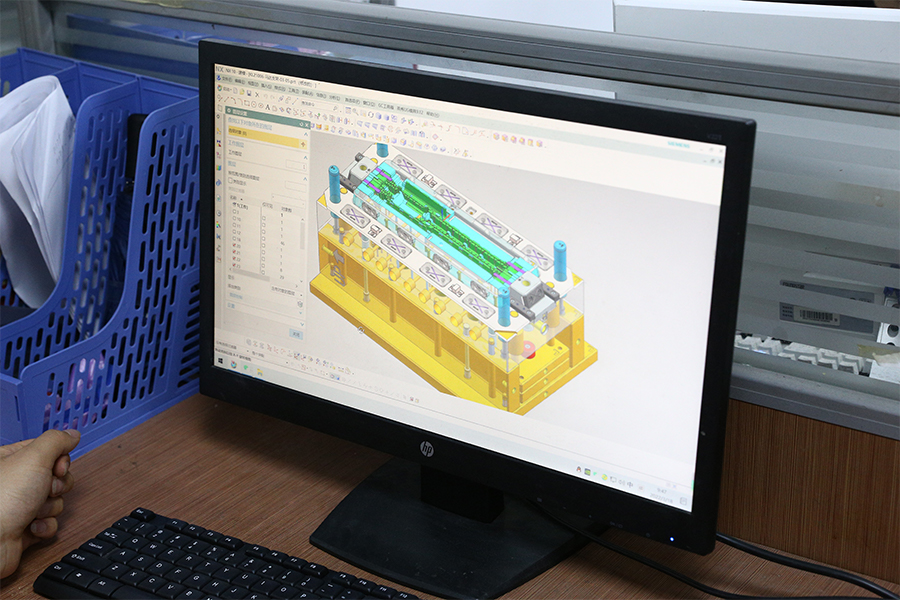

We have our national R&D studio for plastic industry technology development. Over the past 10 years, Kelong has already gained more than 100 certificates of patents in mold design, mold structure making, plastic components invention, plastic parts functional improvement as well as new inventions of plastic field.

Kelong R&D has achieved solutions like gas assistant plastic molding technologies, water injection plastic molding technologies, high light injection molding, stacking molding, multi-color injection molding, foam injection molding and so on. All these are the latest plastic industry technology in Europe. Therefore, Kelong is ranking the top of Chinese mould makers and gains a unique advantage in the molding market.

Our technical team can draw upon many years of experience from the multiple disciplines that are required to develop a successful molded product. We analyse the component design of all new projects and apply our experience of ‘design for manufacture‘ to maximize mould ability, minimize second operations, reduce assembly time and simplify tooling – adding value at every stage, resulting in the ideal combination of material, mold, manpower, and machine for efficient and cost-effective production.

The thin-wall design for disposable takeout container molds has now become a core trend. It significantly reduces material consumption, enhances production efficiency, and responds to environmental de...

Fan blades are essential components in various appliances such as fans, cooling fans, and air conditioners. The core objective of a fan blade mold is to produce blades with high efficiency, low noise,...

Beer boxes are common logistics turnover boxes in our daily life, and beer box molds are also one of the most frequently received molds by various mold companies. A plastic beer case, which will carr...

In injection molds, PET transparent product molds are the touchstone of the highest standards. Any defect will be very obvious on the product. This type of product is very prone to problems such as fo...

Under the dual impetus of the global plastic ban and the low-carbon goal, the market for degradable plastics is growing rapidly at a rate of over 20% annually. More and more enterprises are either usi...

Eighty percent of the key and difficult points of motorcycle helmet molds lie in the design stage. A set of high-quality full helmet molds, from design to stable mass production, usually takes 3 to 6...