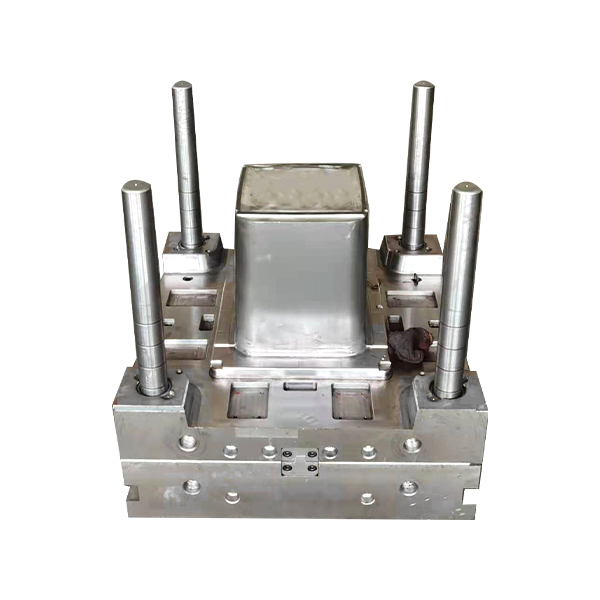

For trash can manufacturers, molds are the cornerstone of production. Their quality directly determines the market competitiveness of the final product, production costs, and long-term profitability. Faced with numerous mold suppliers in the market, how can you make an intelligent choice, avoid falling into the "low-price trap," and prevent endless production headaches down the line? This guide will systematically outline the key dimensions for evaluating both mold quality and the supplier, helping you find the most reliable partner.

- 1.Design Rationality: A Solid Foundation is Crucial.

An excellent supplier will provide a detailed DFM (Design for Manufacturability) analysis before design begins, identifying potential injection molding issues with the product structure (such as sink marks, trapped air, or stress concentration) and proposing optimizations. Evaluate whether the mold structure is simple and reliable. Pay close attention to: whether the draft angle is sufficient (to avoid product scuffing), whether the cooling systemis uniform and efficient (dictating cycle time and product warpage), and whether ventilation is adequate (to avoid burn marks or short shots). - 2.Processing Precision and Craftsmanship: Craftsmanship Determines Product Quality.

Does the supplier possess high-precision equipment such as CNC machines, deep-hole drills, slow wire EDM, and mirror finish EDM? The level of equipment directly impacts the precision of the mold.Surface Treatment: Observe the polishing grade of the mold surface. The interior walls of a trash can typically require a mirror or high-gloss polish (to facilitate demolding and cleaning), while the exterior may require a texture (grain). The uniformity, clarity, and consistency of the texture are a direct reflection of craftsmanship level.Fit and Tolerances: Check whether the parting surfaces, sliders, and other mating parts fit tightly, without excessive gaps or misalignment. This relates to the size of flash (burrs) on the product.

- 3.Effective Communication: The Human Factor Matters.

A mold is an inanimate object, but a supplier's service is active. A reliable supplier is more important than just a good mold.

During initial communication, can their engineer accurately understand your requirements and offer professional insights? Is their response timely?

Do they have proven experience in successfully producing molds for similar trash cans (especially complex styles like those with built-in compactors or smart sensor lids)?

When problems arise, what is their response time? Can they provide prompt on-site repair or technical support?

Choosing a trash can mold is a significant investment decision. It is not merely purchasing a production tool, but selecting a partner who can safeguard your stable production for years to come. By following the advice above and maintaining a professional and prudent approach, you will undoubtedly be able to identify that "golden key" supplier who will create sustained value for you.

English

English Español

Español

.jpg)

.jpg)