We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Follow us:

Please scan the code

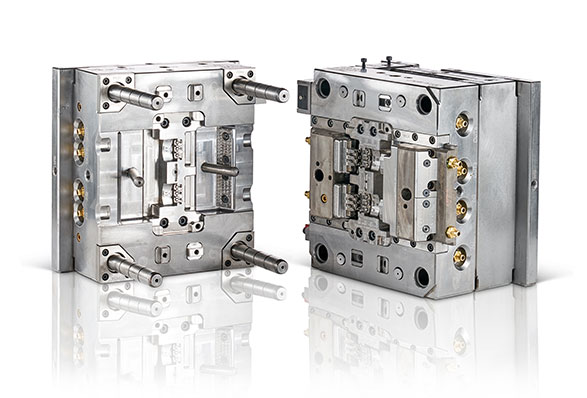

The surface of a fan blade is curved, with edges featuring arcs, and the precision requirement often reaches ±0.03mm or even higher. Any machining error can disrupt the blade's balance. Thus, fan blade molds require high-precision machining: it is essential to use five-axis high-speed CNC milling for fine machining. This demands top-tier machine accuracy, toolpath planning, and programming expertise.

Fan blades typically have uneven wall thickness, with the edges being the thinnest. Uneven cooling can lead to shrinkage and warping. Moreover, it is crucial to ensure that every blade produced is identical in weight and shape. Even a few milligrams of weight variation in a single blade can cause severe vibration during high-speed rotation. Therefore, KELONG MOULD implements absolute symmetry and balance in mold design: comprehensive mold flow analysis must be conducted before mold opening to accurately predict issues, optimize gate locations, cooling channels, and pressure-holding curves, addressing problems at the design stage.

The runner design of the mold must ensure absolutely uniform filling of each blade. Precision venting slots are incorporated at the parting lines, insert interfaces, and ejector pins to achieve filling. We create conformal cooling channels inside the core that closely follow the blade's curved surface, enabling synchronous and uniform cooling.

To enhance blade strength, customers often incorporate additives such as calcium carbonate and glass fibers during production. These materials are corrosive. Therefore, we use high-hardness, high-wear-resistant mold steel and apply nitriding treatment to ensure zero wear in the cavity during long-term production, maintaining precision over time. We design sophisticated ejection mechanisms composed of angled lifters and sliders to ensure the blades are released undamaged from the complex cavity. Additionally, we employ a precision inspection system: not only are dimensions checked, but the blades undergo full-surface scanning and comparison, and dynamic balancing machines are used to test blade balance. This ensures the blades produced are stable in quality and operate silently.

KELONG MOULD is a professional fan blade mold manufacturer, offering integrated solutions from mold manufacturing to product production for our clients.

We guarantee the ability to produce high-quality blades even after millions of injection molding cycles. If you are interested, please contact us.

whats app +86 17705763696

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM The Precision Art of Fan Blade Molds etc.

Kelong Mould is a famous China The Precision Art of Fan Blade Molds suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology The Precision Art of Fan Blade Molds maker.

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

If necessary, we can send engineers to debug, or you can arrange person to train in Kelong to learn mold debugging and maintenance.

We will perform

1. 1-year warranty . 2. The die life of Kelong is more than 500,000 steps . 3. Kelong provides life-long technical services.

We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Please scan the code