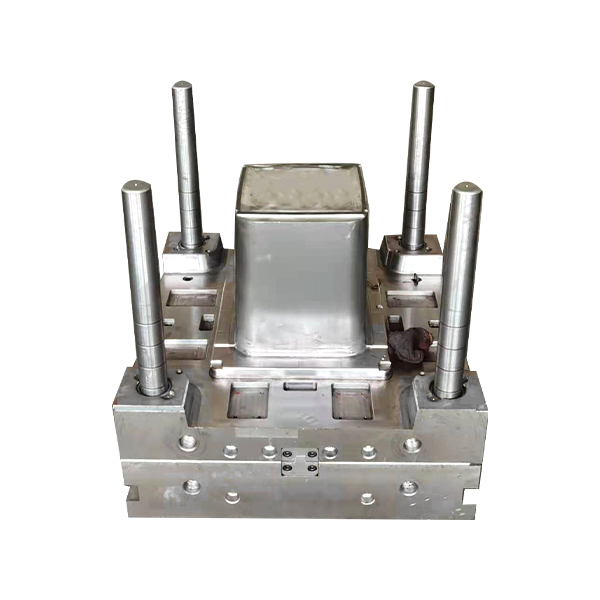

The thin-wall design for disposable takeout container molds has now become a core trend. It significantly reduces material consumption, enhances production efficiency, and responds to environmental demands, all while ensuring sufficient strength for use. Compared to traditional molds, thin-wall takeout container molds present greater challenges and face extraordinary difficulties.

The wall thickness of thin-wall takeout containers is often below 0.6mm, even reaching 0.3-0.4mm. Plastic flows within an extremely narrow space, where resistance increases dramatically. It requires rapid filling to prevent premature cooling while also enabling fast molding and smooth demolding. Simultaneously, the risk of trapped air surges significantly, as even minor venting issues can lead to burn marks or short shots.

Kelong recommends using high-quality steel with high hardness, high toughness, and high thermal conductivity. The Swedish ASSAB series (e.g., S136, XW-42) is an choice. Good thermal conductivity accelerates heat dissipation, while high hardness ensures long-term resistance to wear and corrosion, laying a solid foundation for mold longevity. The steel surface can be treated with PVD coatings such as Titanium Nitride (TiN) or Diamond-Like Carbon (DLC), which significantly reduce the friction coefficient, enhance wear and corrosion resistance, and improve release performance—crucial for preventing sticking.

Due to the thin walls, the part has low structural strength. The ejection system design must be extremely precise, as any imbalance or minor burr can cause ejection pin penetration or part deformation. The ejection system should prioritize solutions like pneumatic-assisted ejection or larger-area full-round ejector pins to ensure smooth demolding.

To address trapped air issues, reliance on a single venting method is insufficient; a comprehensive venting system must be constructed. Parting line venting is primary, while venting through inserts and ejector pins is key to solving trapped air in ribs or complex structures. For thin-wall takeout container molds, venting issues cannot be completely resolved after trial molding. A good mold designer must plan systematically during the design phase. These micron-level venting channels are highly susceptible to clogging from oil stains, dust, or residual plastic. During mold maintenance, specialized vent groove cleaning tools must be used for meticulous cleaning. Scratches from hard objects like steel pins are strictly prohibited.

Every successful reduction in wall thickness for thin-wall disposable takeout container molds relies on the mold engineer's in-depth exploration of limits and relentless pursuit of precision. For decades, Kelong Mould has helped dozens of enterprises improve cost reduction and efficiency enhancement for their thin-wall takeout container products. We firmly believe that only through continuous technological innovation can we achieve greater competitiveness in the future.

Whatsapp :+86 17705763693

Email: [email protected]

English

English Español

Español

.jpg)

.jpg)