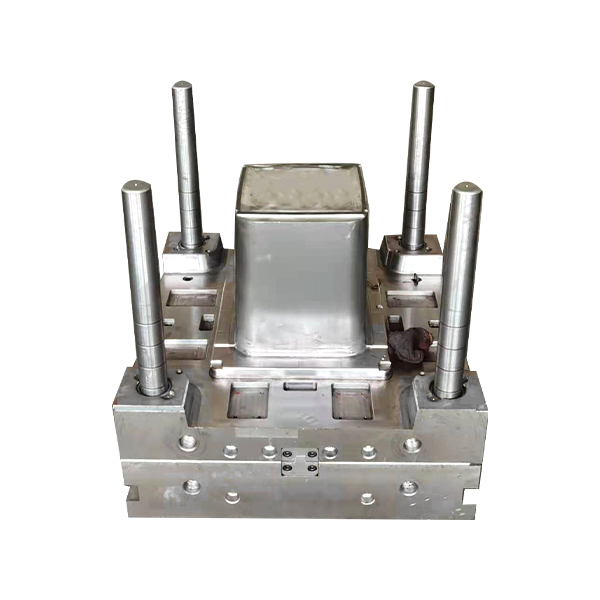

Eighty percent of the key and difficult points of motorcycle helmet molds lie in the design stage. A set of high-quality full helmet molds, from design to stable mass production, usually takes 3 to 6 months or even longer.

A complete plastic helmet is usually composed of a shell, goggles and ventilation parts (some helmets have chin rests and tail wings). The commonly used material for shells is ABS, and the commonly used material for goggles is PC.

Helmet molds are different from ordinary shell molds. Their uniqueness lies in the fact that helmets are protective products and must strictly comply with safety standards. This requires uniform wall thickness, complete structure, and the ability to withstand strong impact forces. The shape of the product must perfectly fit the curve of the human head. The parting line must be designed in an invisible or aesthetically pleasing position. The selection of the gate location needs to be confirmed with the customer and it should be placed in a concealed area (inside the lower edge). If the client needs to do a textured skin, it must be determined at the design stage. Because the texture of the leather will increase the demolding resistance, the draft angle needs to be increased accordingly.

Goggles mold: The optical requirements for the product are very high. Goggles are transparent curved products, and the product requires high transparency, no impurities, no bubbles, and no flow marks. The runner and cooling design of the mold must be extremely uniform; otherwise, it will cause the lens to distort and deform, resulting in dizziness for the user and affecting the clarity of vision. The mold steel must be selected from high-grade stainless mold steel (such as S136), and the surface polishing of the mold should be done to the extreme.

Motorcycle helmets are generally classified into four types: Full Face Helmet , Modular Helmet , 3/4 Open Face Helmet and Open Face Helmet .

The full face helmet completely covers the head and offers good protection. The full face helmet mold is the complex and costly helmet mold. The core difficulty lies in the one-piece molded large shell, while also taking into account the complex internal ventilation ducts and vents, as well as ensuring precise assembly with the goggles. The full face helmet mold has high requirements for the draft Angle. Designers must find suitable draft Angle to ensure that the product does not rest on the mold and does not deform when it is taken out.

The chin part of the Modular Helmet can be lifted upwards as a whole, taking into account both the protection and convenience of the full face helmet. When designing the mold, in addition to the shell itself, the installation of the shell and the chin rest also needs to be considered, and the assembly requirements for plastic parts are even higher

The 3/4 Open Face Helmet is characterized by no chin protection, an open face and ear protection. The mold structure is relatively simple, and customers usually pay more attention to the appearance design of the product

The Open Face Helmet only covers the top of the head, is the smallest in size, the lightest and has the weakest protection. The mold should have the simplest structure, with a shallow mold cavity and few slider mechanisms. Generally, the mold cost is low and the cycle is the shortest. However, if a complex appearance of leather texture is required, the surface treatment requirements are high.

English

English Español

Español

.jpg)

.jpg)