We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Follow us:

Please scan the code

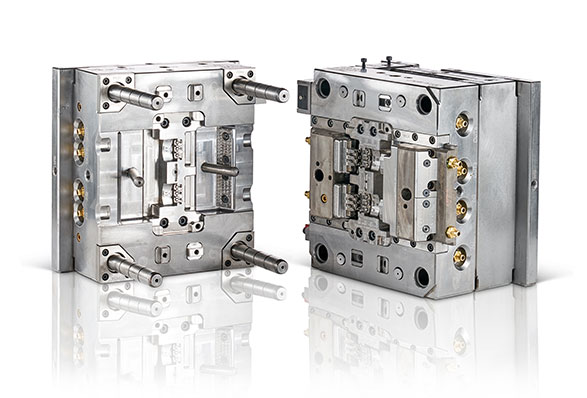

As a professional chair mold manufacturer, we have learned from our communication with customers that they always have the same troubles. For instance, problems such as chair deformation, surface flaws, or low mass production yield. This is often not because the product design is poor, but because the "genes" of the chair mold determine the upper limit.

The core of a chair mold lies in balancing precision and efficiency. KELONG MOULD will conduct CAE simulation and DFM analysis before the project starts. Understand the customer's plastic materials and adjust the design plan based on the material characteristics. Meanwhile, we have established a complete database of chair trial molds, accumulating process parameter libraries for chairs of different structures (such as hollowed-out chairs, stacked chairs, and office chairs), which can significantly shorten the development cycle of subsequent projects.

The biggest challenge in making a plastic chair is that it is particularly prone to trapped air, deformation and surface microcosm after injection molding. To solve this problem in advance, we used professional software (mold flow analysis) on the computer to simulate in advance how the plastic melt flows and cools in the mold. This way, it is possible to predict how the chair will deform and where problems will occur after demolding.

Based on this simulation result, we can precisely design the flow channels and cooling water channels inside the mold, with the aim of ensuring that the plastic can evenly and synchronously fill every corner of the mold and also cool evenly. This step is fundamental to preventing deformation.

If the computer predicts that a certain part of the chair will deform, we design anti-deformation when manufacturing the mold, which means adjusting the deformation Angle in the opposite direction of the product's deformation. When a product undergoes natural shrinkage and warping after demolding, it tends to return to its original designed shape. In this way, high-quality chairs with stable dimensions and smooth appearances can be produced.

The armrests of chairs, irregular-shaped backrests and other structures require multi-directional core-pulling. The movement of multiple sliders in a limited space is prone to interference, which is one of core and challenging problems in the design and manufacture of chair molds. When opening the mold, multiple sliders must act in a strict sequence either successively or synchronously. When closing the mold, precise reset is even more necessary. Moreover, for the sake of product aesthetics, the parting line and the slider joint seams must be ingeniously concealed in areas that are not touched by hand or visually obvious. KELONG MOULD gives customers only one result: the mold stably and efficiently produces high-quality chairs without jamming, without mold collisio or troublesome maintenance.

KELONG MOULD has been dedicated to chair mold manufacturing for 20 years. We have delivered more than 300 sets of large chair molds for globally renowned furniture brands. If you are troubled by how to produce high-quality chair products, we welcome you to discuss the technical details with us.

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM How to improve the production quality of chair molds etc.

Kelong Mould is a famous China How to improve the production quality of chair molds suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology How to improve the production quality of chair molds maker.

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

If necessary, we can send engineers to debug, or you can arrange person to train in Kelong to learn mold debugging and maintenance.

We will perform

1. 1-year warranty . 2. The die life of Kelong is more than 500,000 steps . 3. Kelong provides life-long technical services.

We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Please scan the code