Injection mold factory processing

1) If the processing pressure is too high, the speed is too fast, the more material is charged, and the injection and pressure holding time is too long, the injection mold factory will cause excessive internal stress and cracking.

2) Adjust the mold opening speed and pressure to prevent the rapid force drawing of the parts from causing demoulding and cracking.

3) Appropriately increase the mold temperature to make the part easy to demould, and the injection mold factory appropriately lowers the material temperature to prevent decomposition.

4) Prevent cracking due to weld line and plastic degradation caused by lower mechanical strength.

5) Appropriate use of mold release agent, injection mold factory pay attention to often eliminate the aerosol and other substances attached to the mold surface.

6) The residual stress of the workpiece can be eliminated by annealing heat treatment immediately after forming to reduce the generation of cracks.

Injection mold factory mold

1) The ejection should be balanced, such as the number of ejector pins and the cross-sectional area should be sufficient, the demolding slope should be sufficient, and the cavity surface should be smooth enough to prevent cracking due to the concentration of residual stress in the ejection caused by external force.

2) The structure of the workpiece should not be too thin, and the transition part should use arc transition as much as possible to avoid stress concentration caused by sharp corners and chamfers.

3) Minimize the use of metal inserts to prevent the internal stress from increasing due to the different shrinkage rates of the inserts and parts.

4) Appropriate demoulding air inlet channels should be set for deep bottom parts to prevent the formation of vacuum negative pressure.

5) The sprue is enough to enable the gate material to be demolded when it has time to cure, so that it is easy to demold.

6) The joint of the sprue bushing and the nozzle should prevent the drag of the chilled material and make the part stick to the fixed die.

Injection mold factory materials

1) The content of recycled material is too high, resulting in low strength of the parts.

2) The humidity is too high, causing some plastics to chemically react with water vapor, reducing the strength and causing ejection and cracking.

3) The material itself is not suitable for the environment being processed or the quality is not good, and the pollution will cause cracking.

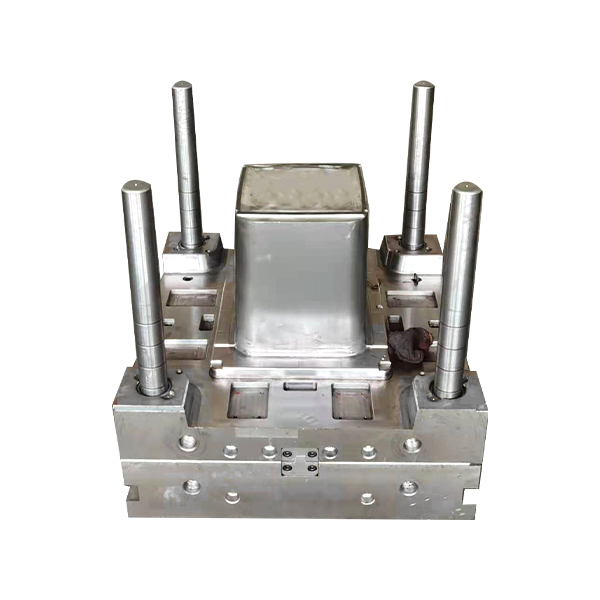

Different injection molds in injection mold factories have different requirements. To sum up, the performance requirements of plastic molds for mold steel are mainly reflected in: hardness, polishing, etching performance, welding performance, wear resistance, toughness, dimensional stability, corrosion resistance performance, etc.

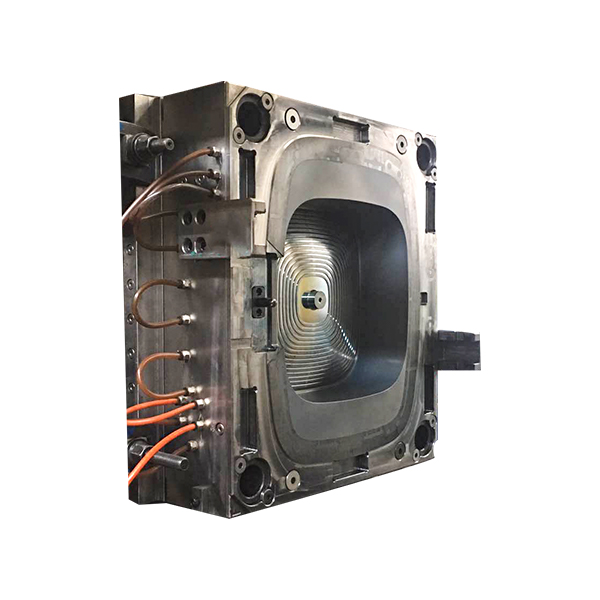

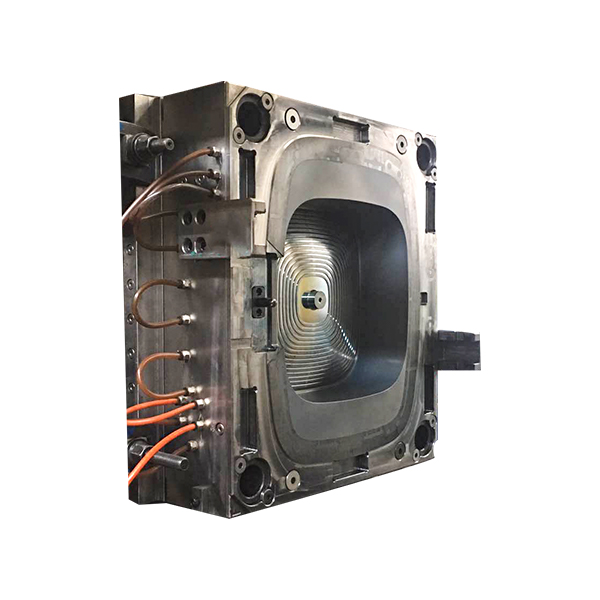

Air Purifier Mould

1. The product forming process, mould structure and manufacturing process are analyzed. To guarantee mould life up to more than 1 million times.

2. The complete mould structure and processing parts must be designed, and the assembly requirements and injection moulding process requirements must be proposed.

3. Causes defects in the appearance of plastic parts (such as shrinkage, etc.) or mould structure problems (such as parting surface setting, gate setting, mould life cannot be guaranteed, etc.). The appearance of the mould must be guaranteed to be free of rust, bump marks, disability and other module defects.

English

English Español

Español

.jpg)

.jpg)