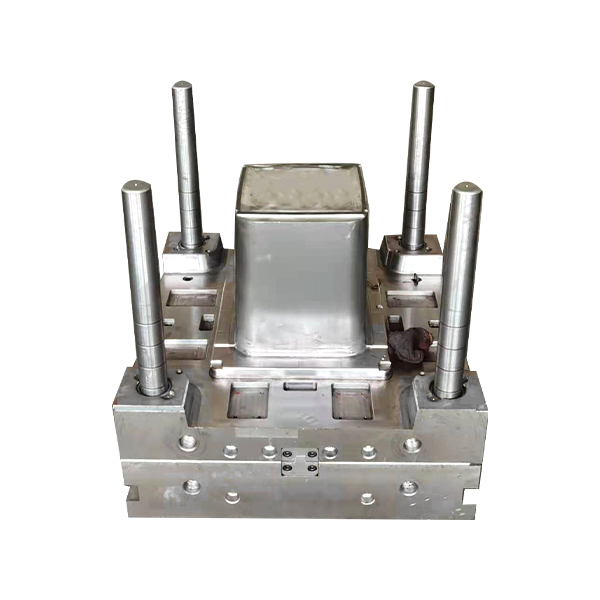

Kelong Mould has developed from an ordinary mould manufacturer to a one-stop procurement supplier from product development, mould manufacturing, injection molding to assembly. The company strictly controls quality, time and cost to create value for customers, and strives to be an excellent brand mold supplier based in China and serving the world.

But a mature factory how to control the quality of the mold?

For the kinds customized project , every step is very important. From the project analysis, mold design, mold tooling, mold assembly. In processing, the tooling machine is the key point to ensure the mold quality.

Kelong has sodick mirror EDM, wire cutting , 5-axis machining centers, mold clamping machines and other high-precision equipment, and has established a complete sales network and customer channels in Europe, South America, the Middle East, North Africa, Southeast Asia and other regions.

Today we are talking about the One of the processing equipment for the CNC Machines.

CNC machines tend to come in three main forms, the first uses basic drill bits that spin at high speed, makes contact with the stock material and removes it where needed. The next use is lathes, these work in reverse to drills by spinning the stock material and cutting off material against a stationary drill bit or cutter. The third and by far the most common are milling machines. These use rotary cutting tools to remove material from a stock piece. They are the most precise and tend to be the go-to CNC machine for creating high-precision engineering pieces. Any removed material usually called “chip” is also removed and can usually be recycled later.

If you would like to know more about other machine or mould, welcome to contact us.

+86-17705763693

English

English Español

Español

.jpg)

.jpg)