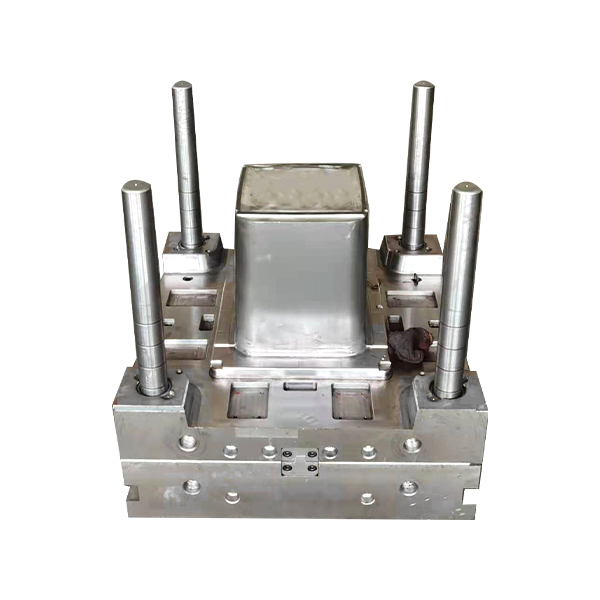

Kelong Mould has enjoyed rich experience in injection molding area, especially for plastic pail mould, and we have made lots of types bucket mould with different size range from 1L to 35L, such as 1L, 2L, 3L, 1gallon, 5L, 6L, 8L, 10L, 12L, 15L, 16L, 18L, 20L, 25L and so on. We could make the paint bucket mould with multi-cavity solution.

A high-quality mold structure is a premise for a qualified mold before manufacturing.We attach great importance to analyze mold structure, including demolding draft angle, the epitome of product surface, gating system design, exhaust design, cooling system design etc.The main problems that may easily occur will through trial and error during the mold structure design.

Th ere have different ways to test the paint bucket sample according to different requirement:

ere have different ways to test the paint bucket sample according to different requirement:

1. stacking: bucket by bucket space saving; whole set by whole set balance and strength inspection.

2. drop testing: when the lid closed with the bucket, we drop the bucket from the height 1m(-1.5m), the lid could not be divided from bucket and caused water leakage.

3. shaking testing: use certain device to test the bucket and lid seal quality.

4. Concentricity: Inspect the wall thickness of the bucket.

5. Weight according to tolerance requirement.

Kelong Mould can help customer to meet from zero to mass production with whole paint bucket molding service, include paint bucket mould, injection molding machine, necessary additional machines and technology support. Welcome to contact us for more information. Thanks.

Whatsapp: +86-17705763693

E-mail: [email protected]

Website: www.kelongmoulds.com

English

English Español

Español

.jpg)

.jpg)