We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Follow us:

Please scan the code

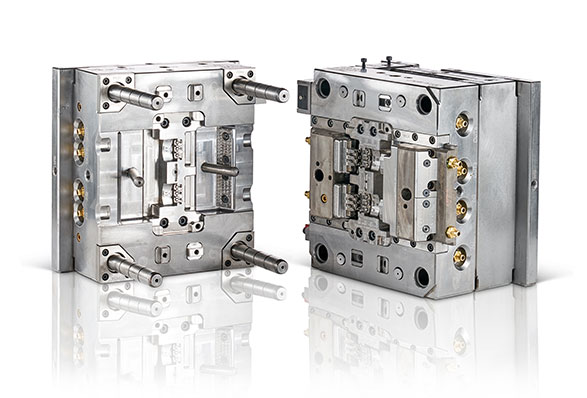

The steel material of the plastic chair mold is generally P20 or 45 steel. To go through forging, CNC milling rough processing, conditioning to 28-30HRC (generally not nitriding), CNC milling finishing and other processing processes. The plastic for injection molding chairs is generally pp, and sometimes calcium carbonate (not more than 20%) is added in order to make the product look full, without miniature. PC (fully transparent) plastic is also useful, but there may be many bubbles due to poor exhaust and other reasons, but the cost is higher, and the surface treatment of the steel is also different.

The chair mold has several special requirements: 1. The parting line is good and does not wear hands; 2. The exhaust effect is better, otherwise the plastic products will have black spots, etc., and serious ones will burn; 3. The superposition effect is better, the stack of 10 chairs is vertical and not inclined, the distance between the feet of the two chairs shall not exceed 60mm when superimposing, and it should be easy to separate after superimposing; 4. The mold should be highly polished, because the chair is a daily necessities, so there can be no flash, burr, etc., to avoid scratching the skin.

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM Plastic Chair Molding etc.

Kelong Mould is a famous China Plastic Chair Molding suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology Plastic Chair Molding maker.

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

If necessary, we can send engineers to debug, or you can arrange person to train in Kelong to learn mold debugging and maintenance.

We will perform

1. 1-year warranty . 2. The die life of Kelong is more than 500,000 steps . 3. Kelong provides life-long technical services.

We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Please scan the code