We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Follow us:

Please scan the code

Ergonomic computer chair

Reclining office chair

The so-called ergonomic computer chair uses ergonomic design, and the use method is as suitable as possible for the natural form of the human body, so that people who can use tools at work, the body and spirit do not need any active adaptation, so as to minimize the fatigue caused by the use of tools. This type of computer chair must meet the following conditions:

①. The headrest is adjustable;

The handrail is adjustable, and can be lifted and lowered at multiple levels, so that the hand and body can maintain the best position with the ground and the computer desk;

3. The backrest can better fit the back, and can effectively relieve spinal fatigue when working at desk for a long time;

④. With lifting function;

The length and width of the seat cushion and the height of the chair must be customized according to the user group. For example, Asians generally have less height and weight than Europeans, so there must be one standard for Asians and another for Europeans.

⑥. Thickened explosion-proof steel plate. Any ergonomic computer chair must be people-oriented, starting from people, with personal safety as the first element, the main role of explosion-proof steel plate to strengthen the role of personal safety protection;

7. Air pressure rod must be SGS international certification;

⑧. The bearing capacity of the tripod should be greater than or equal to 500kg. The test method can use the car to press over the tripod one by one to confirm the load-bearing capacity

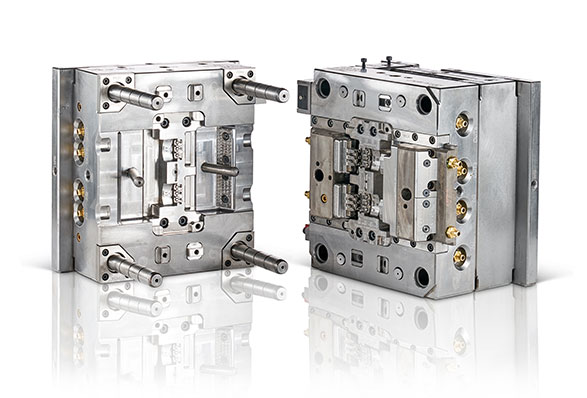

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM Computer Chair Mold etc.

Kelong Mould is a famous China Computer Chair Mold suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology Computer Chair Mold maker.

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

If necessary, we can send engineers to debug, or you can arrange person to train in Kelong to learn mold debugging and maintenance.

We will perform

1. 1-year warranty . 2. The die life of Kelong is more than 500,000 steps . 3. Kelong provides life-long technical services.

We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Please scan the code