We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Follow us:

Please scan the code

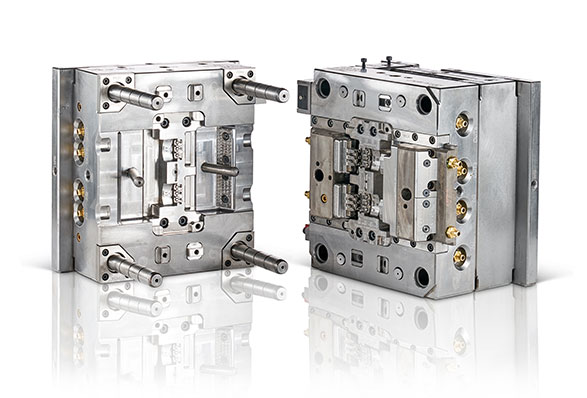

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM Children's Back Chair Mould etc.

Kelong Mould is a famous China Children's Back Chair Mould suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology Children's Back Chair Mould maker.

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

If necessary, we can send engineers to debug, or you can arrange person to train in Kelong to learn mold debugging and maintenance.

We will perform

1. 1-year warranty . 2. The die life of Kelong is more than 500,000 steps . 3. Kelong provides life-long technical services.

We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Please scan the code