We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Follow us:

Please scan the code

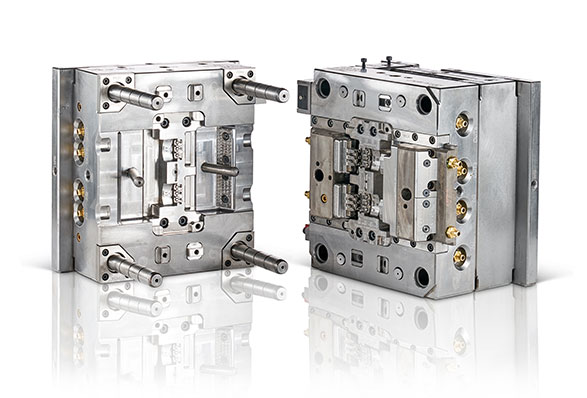

Proper maintenance and care of chair mold not only ensure the stability of product quality but also extend the service life ofchair mold several times, thereby significantly reducing the production cost per piece of products. We will systematically explain the key points of chair mold maintenance for you to help customers achieve long-term production.

Q

Maintenance in daily production

Q

1.Standardized operation: Ensures that the ejection of the ejector pin is stable and smooth, without any tilting or jamming. Adjust the appropriate ejection stroke to avoid excessive impact or wear of the ejector pin. Keep parameters such as injection pressure and clamping force within a reasonable range to avoid damaging the chair mold due to overload.

Q

2.Daily cleaning: After each shift of production, the residual plastic, oil stains and moisture in the parting surface, cavity, runner and exhaust groove of the mold must be thoroughly cleaned with an air gun, soft cloth and special cleaning agent. It is strictly prohibited to forcibly scrape with hard metal tools to avoid scratching the surface of the cavity.

|

3.Continuous rust prevention: In damp environments or during the rainy season, rust inhibitors should be placed inside the chair mold or rust prevention devices should be installed. Special anti-rust oil must be sprayed on the forming surface of the mold after cleaning.If the mold needs to be stored for a long time (more than 3 months), high-quality anti-rust grease should be applied to all forming surfaces and processing holes, and it should be stored in a dry, dust-free and constant-temperature environment Q 4.Record: Hang an identification plate on the mold, indicating the maintenance date and the next maintenance reminder. |

|

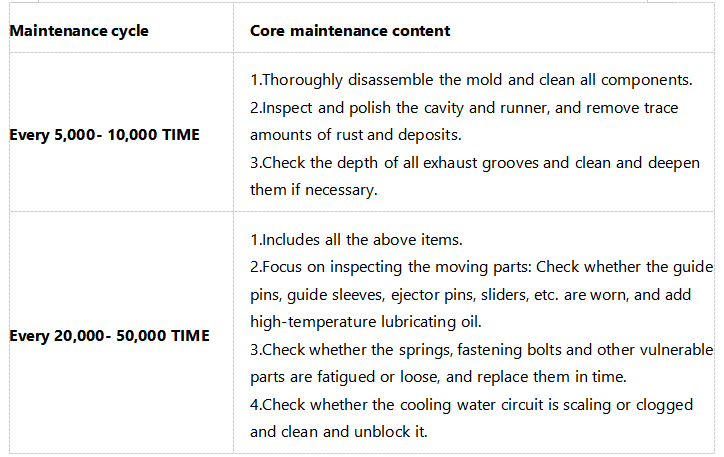

Regular Maintenance: In-depth physical examination and repair

The entire life cycle of a set of chair mold begins with outstanding design and manufacturing and is accomplished through scientific and meticulous maintenance. As your reliable mold manufacturing partner, KELONG MOULD not only provides high-quality molds, but is also willing to offer customers all-round technical support.

Take immediate action and incorporate mold maintenance into your production management system. Welcome to contact our expert team at any time. We will provide you with customized mold maintenance solutions!

Email: [email protected]

Phone Number/WhatsApp: +86 17705763693

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM Chair Mold Maintenance And Care Guide etc.

Kelong Mould is a famous China Chair Mold Maintenance And Care Guide suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology Chair Mold Maintenance And Care Guide maker.

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

If necessary, we can send engineers to debug, or you can arrange person to train in Kelong to learn mold debugging and maintenance.

We will perform

1. 1-year warranty . 2. The die life of Kelong is more than 500,000 steps . 3. Kelong provides life-long technical services.

We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Please scan the code