We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Follow us:

Please scan the code

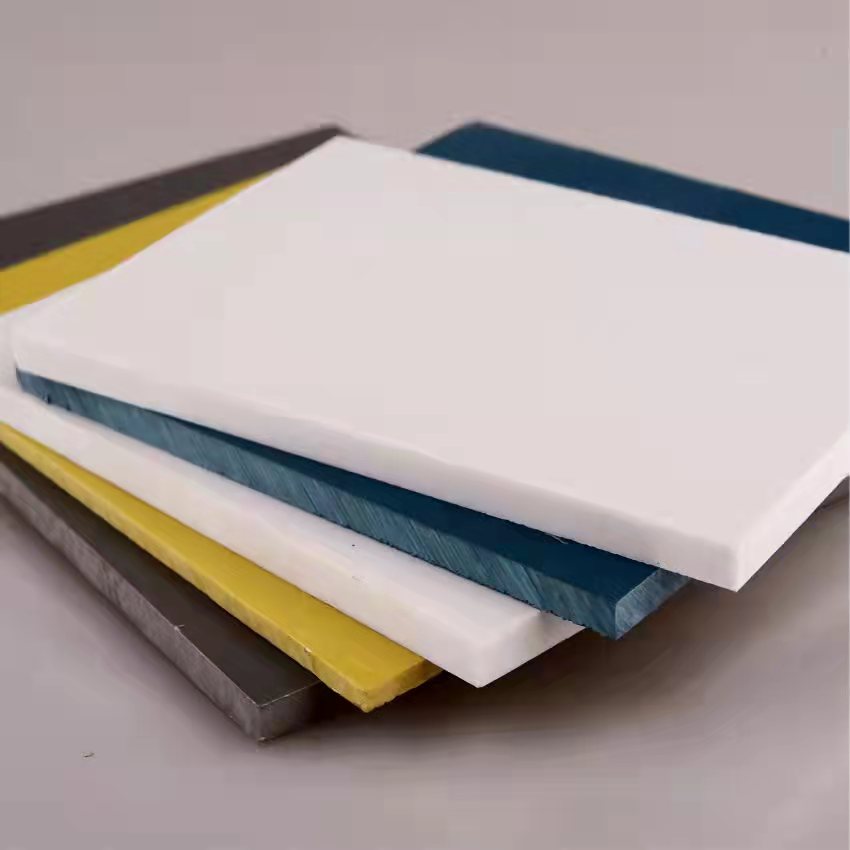

Plastic board: Plastic board is made of plastic, plastic is a synthetic polymer compound, you can freely change the shape. Plastic is the use of monomer raw materials to synthesize or condensation reaction polymerization of materials, by synthetic resin and filler, plasticizer, stabilizer, lubricant, color additive composition, its main component is synthetic resin.

Plastics are also divided into general use plastics and engineering plastics, mainly defined by the universality of use, such as PE, PP cheap, can be used in a variety of different types of machine production. Engineering plastics are more expensive, but the raw material stability and physical properties are much better, in general, it has two characteristics of rigidity and toughness.

PVC transparent plastic board: The introduction of foreign advanced technology, the selection of advanced imported raw and auxiliary materials produced by a high-strength, high-transparent plastic board. Product color has white, sapphire blue, brown, brown and other varieties. Thickness :2mm-20mm.1220mmx2440mm 1300mmx2000mm with double-sided transparent die on the surface of the product. Performance characteristics: The product has high strength, high transparency, good weather resistance, non-toxic, health, physical properties are better than plexiglass. Application: The products are widely used in equipment protection board, instrument shell, interior decoration, drinking water tank, liquid level display and so on.

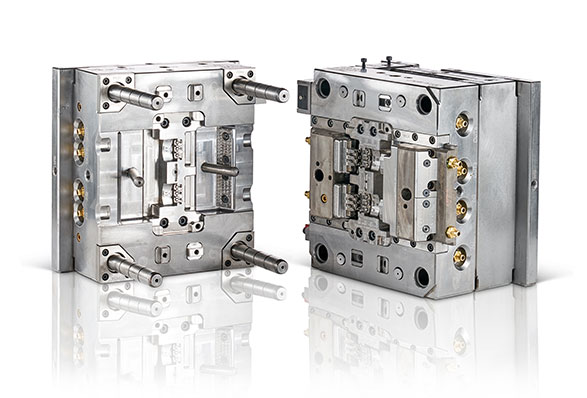

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM Plastic Plate Mold etc.

Kelong Mould is a famous China Plastic Plate Mold suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology Plastic Plate Mold maker.

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

If necessary, we can send engineers to debug, or you can arrange person to train in Kelong to learn mold debugging and maintenance.

We will perform

1. 1-year warranty . 2. The die life of Kelong is more than 500,000 steps . 3. Kelong provides life-long technical services.

We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Please scan the code