We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Follow us:

Please scan the code

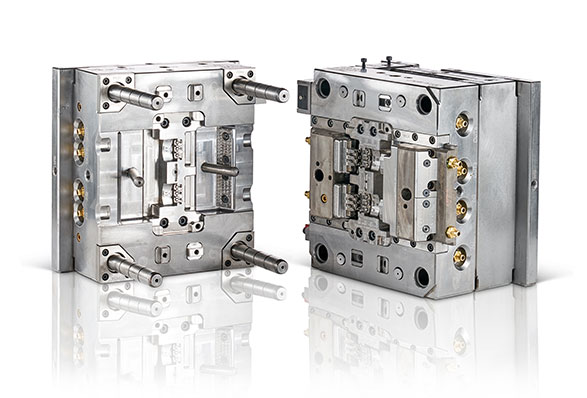

Plastic crates play a significant role in various industries due to their easy cleaning, long service life and resistance to damage. However, poor-quality crate molds often led to low production efficiency, high product scrap rates, and continuous maintenance costs, ultimately eroding the profit margins of customers. Kelong Mould will reveal to you the five key elements of high quality logistics box molds to help you make wiser investment decisions.

1.Crate mould

For crate mould, we recommend and use pre-hardened steels such as P20H/P20+Ni, 718H, 1.2738, etc. The cavity and core require extremely high wear resistance and anti-deformation capacity to cope with the huge clamping force and the wear of the glass fiber filling material (if applicable). We can also carry out surface nitriding treatment on steel to greatly extend its service life

2.Efficient cooling system design

The logistics crate is a thin-walled large product, and the cooling time directly determines the efficiency. We adopt "3D conformal waterways" or carefully designed multi-layer series waterways to ensure uniform and rapid cooling. By optimizing the cooling process, we have successfully reduced the cooling time of a standard logistics box from 18 seconds to 12 seconds, which means that production efficiency has increased by more than 30%.

3.Mature ejection and exhaust system

Logistics crate have a large surface area and are prone to sticking to molds. We adopt the schemes of pushing plate ejection or cylinder ejection to ensure smooth and rapid demolding of the products without any white top. Design sufficient exhaust slots at the parting surface and slider positions to prevent defects such as charring and insufficient filling caused by trapped air.

4.Designed for automated production

Our ctate mold design is fully compatible with the "mechanical hand automatic part picking" and "stacking" systems. For instance, optimize the position of the ejector pins to avoid interference with the mechanical hand, and design a reasonable demolding Angle to facilitate the smooth detachment and automatic stacking of the boxes. Our molds are prepared for modern, efficient and unmanned workshops, not merely for manufacturing products.

5.Maintainability and long-life design

Standardized mold frames and accessories are adopted to facilitate customers' quick replacement. Provide spare parts packages for vulnerable parts (such as sliders and inclined tops). We offer a one-year warranty and lifetime service. As long as you purchase molds produced by Kelong mould, our professionals will continue to serve you

/

Our client is a large logistics company in the United States. The old molds are inefficient and the box damage rate is high. We customized a set of automated crates with 3D waterways for them mould. The molding cycle time was reduced from 55 seconds to 38 seconds, the stability of box stacking was improved by 50%, and the customer recovered the mold investment within six months.

Contact us immediately for a free manufacturability analysis of your crate mould design

Email: [email protected]

Phone Number/WhatsApp: +86 17705763693

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM Durable & Cost-Effective Plastic Crate Mould etc.

Kelong Mould is a famous China Durable & Cost-Effective Plastic Crate Mould suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology Durable & Cost-Effective Plastic Crate Mould maker.

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

If necessary, we can send engineers to debug, or you can arrange person to train in Kelong to learn mold debugging and maintenance.

We will perform

1. 1-year warranty . 2. The die life of Kelong is more than 500,000 steps . 3. Kelong provides life-long technical services.

We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Please scan the code