We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Follow us:

Please scan the code

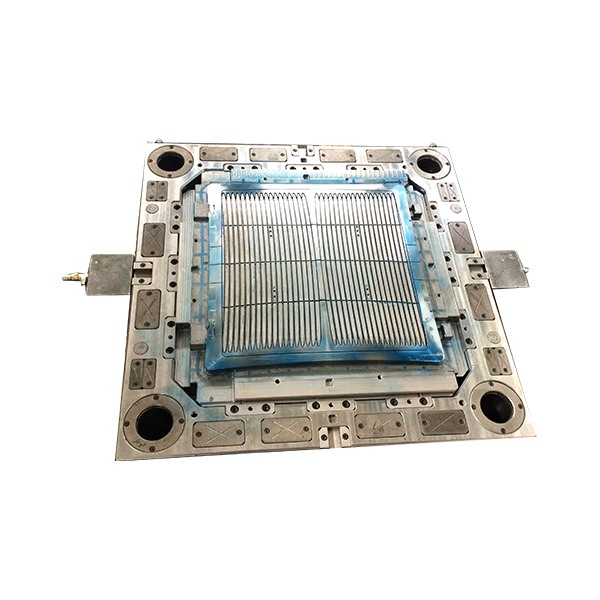

For Air Conditioner Mould, it is necessary to choose the appropriate steel material, because the surface needs high-gloss treatment, so the steel we choose ASSAB s136 from Sweden or NAK80 from Datong from Japan.

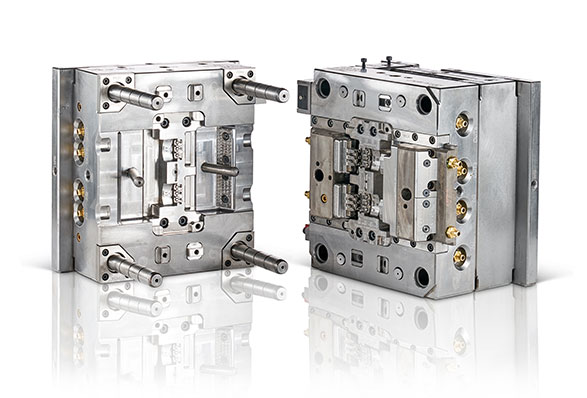

Air conditioner housing Moulds and home appliance air conditioner mould, industrial center air conditioner mould and so on. Kelong Mould makes very well mould-flow analyzing to avoid front mask jointing line. High-speed precise CNC milling, and rigorous quality controlling processing. Here below are the few features and specifications of Kelong mould's air conditioner mould.

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM Central Air Conditioning Shell etc.

Kelong Mould is a famous China Central Air Conditioning Shell suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology Central Air Conditioning Shell maker.

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

If necessary, we can send engineers to debug, or you can arrange person to train in Kelong to learn mold debugging and maintenance.

We will perform

1. 1-year warranty . 2. The die life of Kelong is more than 500,000 steps . 3. Kelong provides life-long technical services.

We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Please scan the code