We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Follow us:

Please scan the code

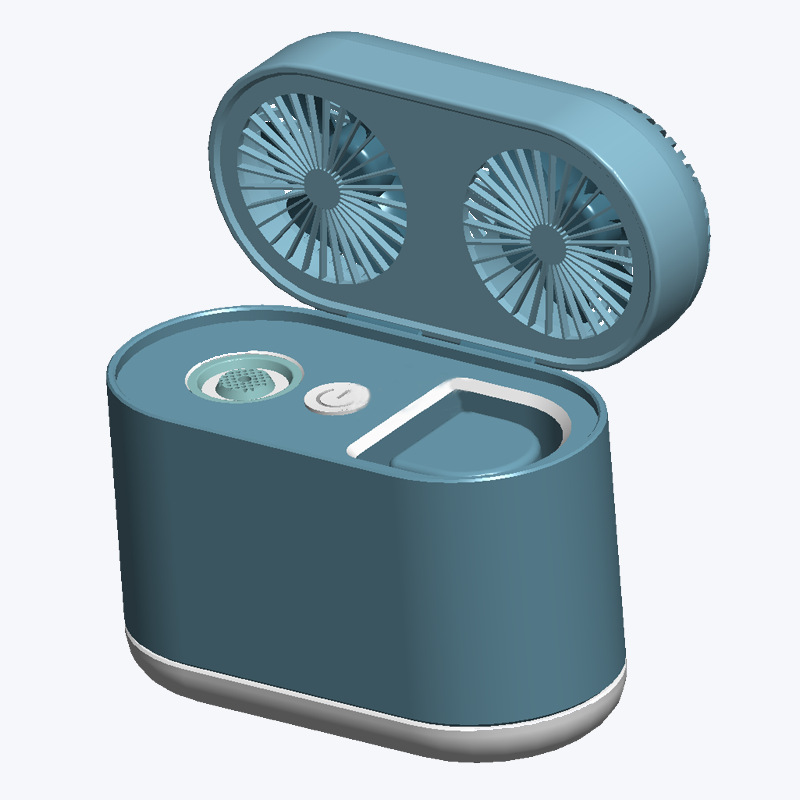

The plastic parts of the electric fan are divided into shell parts, blades, bases, diversion rings, switches and brackets from the structure. These plastic parts from the material can be divided into ABS, PP and other types, different types of plastic parts have different characteristics and uses.

The shell is usually composed of two plastic sheets, separated by a grid-like structure, which can prevent scratching and ensure the strength of the shell. The base is composed of several plastic parts, and the plastic parts are connected through nesting or lap, with high precision and good close-fitting, which can better fix the electric fan in use and make the electric fan more stable. The blade and the guide ring are one of the three components of the electric fan, which are etched and formed by the fan. The plastic support parts supporting the blade solve the separation problem between the blades well, and the level is more stable.

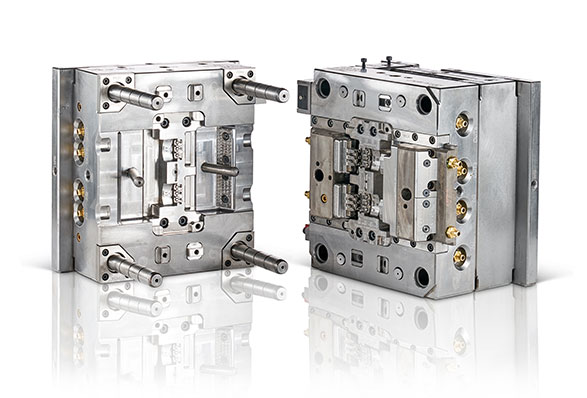

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM Electric Fan Shell Mold- etc.

Kelong Mould is a famous China Electric Fan Shell Mold- suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology Electric Fan Shell Mold- maker.

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

If necessary, we can send engineers to debug, or you can arrange person to train in Kelong to learn mold debugging and maintenance.

We will perform

1. 1-year warranty . 2. The die life of Kelong is more than 500,000 steps . 3. Kelong provides life-long technical services.

We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Please scan the code