There are several types of plastic crates. Some are made of low-density polyethylene (LDPE) or polypropylene. These plastic crates are used for packing parts, machinery, hardware, and even chemical objects. They are generally thick in wall thickness and require special strength testing. Some require flame retardants and anti-alkali properties. The type of material used in making plastic crates depends on its application.

The material used to make plastic crates varies, but most are made of high-density polyethylene (HDPE) which is known for its durability. The material is also known for its anti-aging, UV-protectants, and scratch resistance. Depending on the type of plastic crate mould you want to make, you can choose from a number of shapes and configurations.

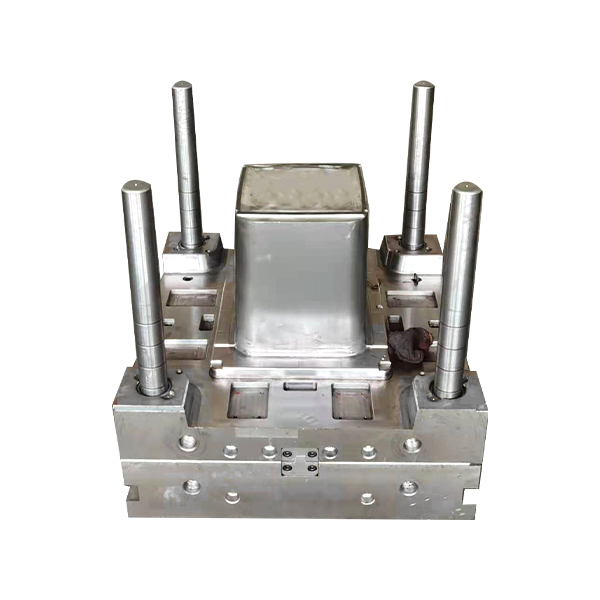

The structure and size of a plastic crate mould are important considerations, as they influence the quality of the molded plastic crates. An ideal mould should be able to meet volume and weight requirements, while being compact and easy to use. These factors will help you reduce your costs and increase your efficiency in molding products.

To make a plastic crate mould, choose a company that has experience in this area. You can trust Taizhou Huangyan Aoxu Mould Technology Co., Ltd., which has over 13 years of experience manufacturing plastic injection moulds. The company is located in Huangyan Taizhou city, also known as the "Mould Town of China".

Plastic crates have many applications in the grocery industry. They provide a more sanitary environment when transporting items and prevent pilferage. In addition, plastic crates are sturdy and rigid and can withstand multiple journeys. They are also easy to clean. They can also be customized to fit any size and shape of goods.

Plastic crates also prevent fish from perishing during transport. Since plastic doesn't conduct heat, it keeps the fish fresh even in harsh weather conditions. Furthermore, it is easier to clean than other materials. Unlike wooden crates, plastic crates can be easily wiped down. The absence of rust makes plastic crates a better option for the fish industry.

Beer box mould and other assembly structure: the main body and bottom cover are assembled in the form of double snaps, the product assembly gap is uniform, the screw column and rib position under the product are most likely to appear microcosm, the beer box mould of Kelong company is in the screw column. The surrounding wall thickness of the mould is reduced by 0.8-1MM, the demoulding slope of the product is designed to be more than 1 degree, and there are ejection structures around the Mould to ensure that the product can be deMoulded smoothly.

English

English Español

Español

.jpg)

.jpg)