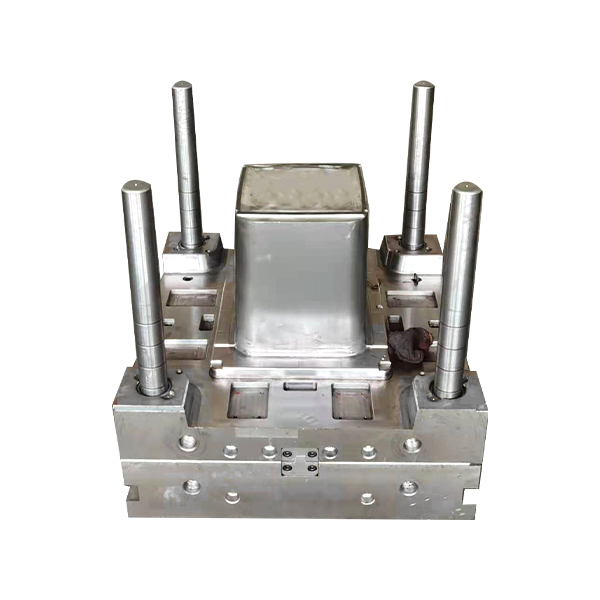

The modern household is filled with appliances and electronic devices designed to make daily tasks more convenient and efficient. Behind the production of these products lies a crucial manufacturing component: the Home Appliance Mould. This essential tool shapes the parts and components that give kitchen appliances and household electronics their form, durability, and functionality. As consumer expectations evolve, the applications of Home Appliance Mould have expanded across a wide range of products, influencing both design trends and production processes.

One of the significant areas where Home Appliance Mould is applied is in the production of kitchen appliances. Products such as blenders, rice cookers, coffee machines, and microwave ovens rely on high-quality moulds to produce consistent, reliable parts. From the outer casings to internal brackets and control knobs, each component is shaped using a dedicated mould to ensure it meets specific dimensions and performance standards.

With consumers valuing both appearance and durability, the role of Home Appliance Mould in creating smooth finishes and precise detailing has become increasingly important. Modern designs often feature sleek lines, compact structures, and functional aesthetics, all of which depend on accurate moulding processes.

Beyond the kitchen, Home Appliance Mould plays a crucial role in the production of various household electronics. Air purifiers, fans, vacuum cleaners, and electric heaters all incorporate numerous plastic and metal parts formed using specialised moulds. The consistency of these parts ensures safe assembly and reliable operation of the finished products.

For example, the external housing of an air purifier not only contributes to the device’s appearance but also impacts airflow and filtration performance. The accuracy of a mould in producing these parts directly affects product quality and consumer satisfaction.

The popularity of compact kitchen gadgets has driven demand for more sophisticated Home Appliance Mould designs. Products like electric kettles, sandwich makers, and handheld mixers require moulds that can handle smaller, intricate components while maintaining dimensional accuracy. Since these gadgets often come in multiple colours and styles, manufacturers rely on versatile mould solutions to produce variations efficiently.

Additionally, with growing attention to user-friendly features such as ergonomic handles and seamless buttons, mould precision ensures that these parts not only look appealing but also feel comfortable and function smoothly.

Many manufacturers now require custom Home Appliance Mould solutions to meet unique product designs and specialised requirements. Customised moulds allow for the creation of exclusive appliance shapes, branded textures, and specialised features that differentiate one product line from another. Whether it’s a non-slip pattern on a vacuum cleaner handle or a specific contour for a modern blender base, a customised Home Appliance Mould makes these design elements possible.

Custom moulding also supports product innovation by enabling rapid prototyping and testing of new ideas. Manufacturers can quickly adjust mould designs to refine functionality and appearance before moving into mass production.

As sustainability becomes a growing priority, energy-efficient appliances are gaining popularity in households worldwide. The development of these products often involves lightweight materials and compact designs, both of which rely on precise Home Appliance Mould processes. For instance, thinner but durable casings for energy-saving fans and air conditioners require moulds capable of maintaining strength while reducing material use.

The application of mould in creating these components contributes to both operational efficiency and reduced environmental impact, aligning with modern market trends.

In household electronics, safety is a key concern. Home Appliance Mould is frequently used to produce components that safeguard both the device and its users. This includes insulation panels, heat-resistant handles, and protective covers for internal circuits. A well-designed mould ensures these safety features fit precisely and perform as intended, reducing risks during appliance operation.

By maintaining consistent production quality, Home Appliance Mould also supports compliance with safety standards and regulations in different markets, helping manufacturers maintain product reliability.

English

English Español

Español

.jpg)

.jpg)