We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Follow us:

Please scan the code

Making an IML (In-mold Labeling) bucket mold is a complex and precise project, which combines traditional injection mold technology with the IML automation system. Next, I will provide you with a detailed breakdown of the production process, key technologies and precautions.

|

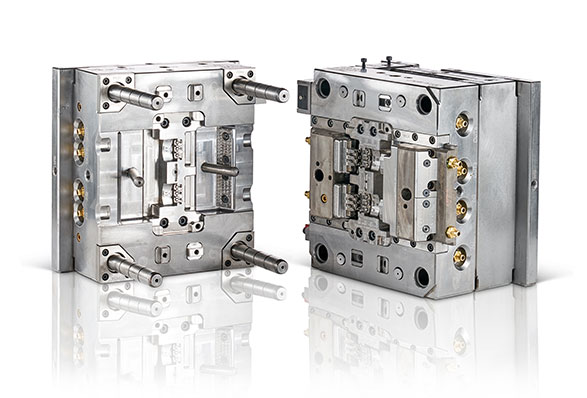

MOULD INFORMATION Mould name:Plastic IML Bucket Mould Product size:10L/20L Number of cavities:1 cavity Mould steel material:P20/718H//NAK80/S136H Mould size:650*650*800mm Suitable for injection moulding machine:450T-650T Hot runner:YUDO/HASCO/Master Ejection system:Push plate ejection Mould cycle time:35S |

First of all, it is necessary to understand the fundamental difference between IML bucket molds and ordinary injection molds:

Ordinary injection molds: Only produce one plastic bucket body.

IML injection mold: During the injection molding process, the pre-printed label is placed inside the mold, allowing the plastic melt to bond with the back of the label (the printed surface), ultimately resulting in a complete product with exquisite decoration that does not require secondary spraying or labeling.

Therefore, IML molds are not merely molds themselves; they are systems that integrate mechanical, electronic, visual and plastic molding technologies.

Material Selection:

The material of the bucket is usually HDPE or PP, and the label material is usually PP or PET film. Its shrinkage rate must match that of the plastic of the bucket body; otherwise, it will wrinkle

Main Difficulty :

|

|

IML bucket molds are generally produced using 450 to 650T injection molding machines. When using injection molding machines with smaller tonnage for production, there will be a problem of insufficient mold opening stroke. The main difficulty of the IML bucker mold lies in how to use electrostatic film. The methods of applying the film and taking the item are divided into top pick and side pick. The customer needs to apply static electricity to the surface of the label through an electrostatic generator to make it adhere to the surface of the bucket. The mechanical hand must be perfectly synchronized with the injection molding machine cycle, with rapid and precise movements and high repeat positioning accuracy (usually within ±0.1mm). |

KELONG MOUULD usually adopt the side-picking IML system. Due to the shorter movement trajectory, a more stable operation effect can be achieved and the in-mold time is shorter. The molds are processed by high-precision CNC and EDM, and finally undergo fine polishing (even mirror polishing) to ensure a smooth surface of the product, which can guarantee a flat appearance after being attached to the mold. The mold injection adopts a needle valve type hot runner to reduce the injection pressure and optimize the molding cycle.

If you would like to discuss more with us about IML bucket mould, you can contact us.

Email: [email protected]

Phone Number/WhatsApp: +86 17705763693

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM How To Make IML Bucker Mold etc.

Kelong Mould is a famous China How To Make IML Bucker Mold suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology How To Make IML Bucker Mold maker.

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

If necessary, we can send engineers to debug, or you can arrange person to train in Kelong to learn mold debugging and maintenance.

We will perform

1. 1-year warranty . 2. The die life of Kelong is more than 500,000 steps . 3. Kelong provides life-long technical services.

We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Please scan the code