Product Description:

To achieve the high gloss on the surface of the air cooler mould, the traditional method is to use a mould temperature machine to heat the mould, but the shortcomings of this method are as follows:

1. Can not meet the needs of rapid heating and rapid cooling in high-gloss injection moulding;

2. The temperature rise is small, and the weld line on the surface of the product can only be reduced but not eliminated;

3. As the plastic hardness is higher, the fluidity is worse. Therefore, the hardness of the surface of the product using this process can only reach the HB level, which cannot meet the actual user needs;

4. Air cooler mould expands when heated up and shrinks when cooled down, making the clamping force very unstable. It is easy to cause various defects such as dissatisfaction, scorching, and large internal stress of the product.

Therefore, based on this process, the steam high-gloss injection moulding technology was developed:

1. This technology opens the water pipe in the air cooler mould. When the temperature needs to be raised, the steam is connected, and when cooling is needed, cold water is used. After the cooling is completed, the residual moisture can be blown out with the compressed air to ensure that rapid heating and cooling can be achieved;

2. To maximize the elimination of various product failures such as weld line clips, watermarks, and lack of glue;

3. Due to the large temperature rise and the use of H or even 2H hardness plastics, the surface hardness of the product is greatly improved;

4. When the pipe is opened inside the air cooler mould, only the inner surface of the mould is heated or cooled, and the overall expansion of the mould is small, thus reducing various product defects caused by unstable clamping force.

To produce high-quality and high-gloss products, it is necessary to cooperate with injection moulding machines, moulds, temperature control equipment, special plastics for high-gloss products, as well as boilers and cooling devices.

About us

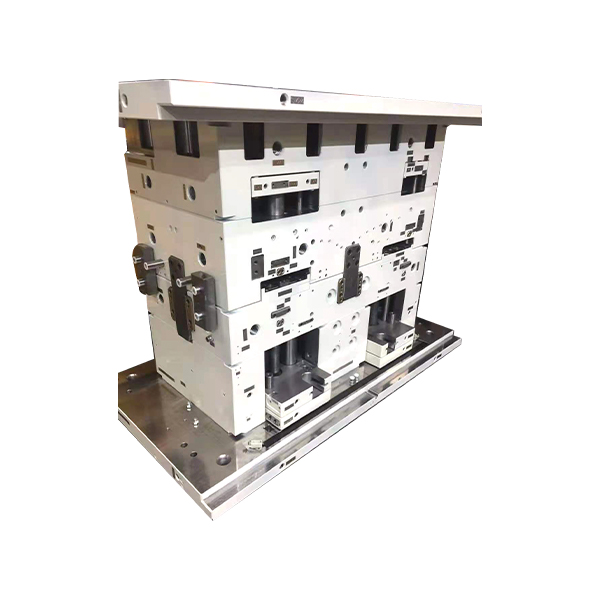

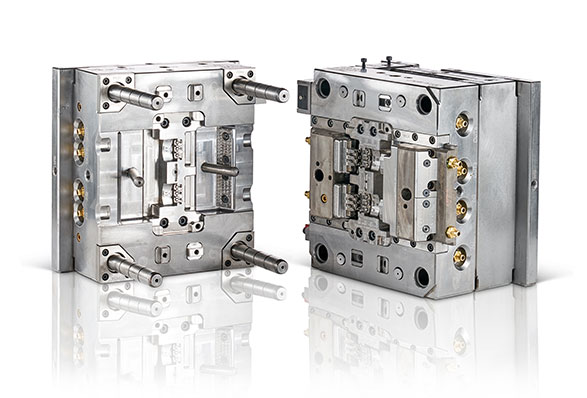

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM Air Cooler Mould etc.

Kelong Mould is a famous China Air Cooler Mould suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology Air Cooler Mould maker.

READ MORE

Serving the world famous

brand mold supplier

Pre-sale service

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

Training and learning

If necessary, we can send engineers to debug,

or you can arrange person to train in Kelong to learn mold debugging and maintenance.

In-sale service

We will perform a mold flow analysis for each mold and provide the analysis report to the customer. When each part is processed, we will conduct quality inspection to ensure that each part is qualified.

After-sale service

1. 1-year warranty .

2. The die life of Kelong is more than 500,000 steps .

3. Kelong provides life-long technical services.