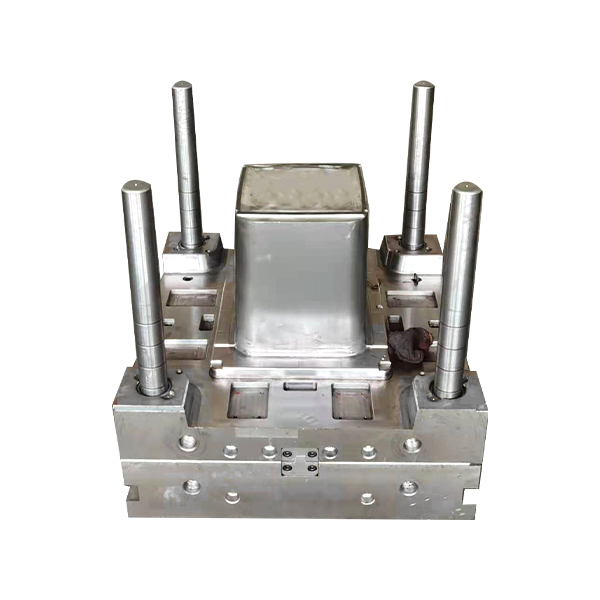

Kelong Mould is professional Plastic Home Applicance Mould Manufacturer in China, we have supplied complete sets of plastic air cooler moulds with different models to our customer for different shape with different size, especailly for 20L,25L,30L,35L,55L and 65L in South Asia, South Africa, Pakistan, India, Iran, Bangladesh, UAE .

Air cooler could help you to make the air temperature cooler or hotter with low cost than air conditioners, but the temperature adjustment range is 5-10 degrees , it not as strong as air conditioners.The air cooler mold steel will be P20/718H with YUDO hot runner or China local hot runner, mold base is SC 45, mold life time is 500,000-1 million shots, mirror polishing surface, external parts will be made of ABS, internal parts will be made of PP, some moving parts or electrical cover will be POM and PA.

Welcome to contact us for air cooler mold,with good processing, reasonable mold structure, short cooling time and easy mold maintenance. Also Kelong Mould will offer you a economical air cooler molds investment solution and share you the air cooler molds injection molding experience help you reduce the mold cost, labor cost and material consumption.

Amanda Evanism

+86-17705763693(wechat/whatsapp)

[email protected]

www.kelongmoulds.com

English

English Español

Español

.jpg)

.jpg)