IML dinner plate mould is a new label packaging form that is different from traditional direct silkscreen printing, heat-shrinkable labels and self-adhesive labels. It has been popular in Europe and the United States for many years.

The IML process is mainly used for injection moulding products of PP, PE, PET and other materials. That is, put the printed in-mould labeling into the injection mould cavity before injection moulding. When the mould is closed for injection moulding, the special adhesive on the in-mould labeling is melted by the action of high temperature and high pressure in the mould, and the same bottle is used. The surface of the body or the injection-moulded part is fused into one. When the mould is opened, a beautifully printed injection part is completed at one time.

IML plate moulds were introduced to China in 2005. At first, in-mould labeling was used as an anti-counterfeiting function in mainland China, because it was difficult for the printing technology to meet the standard of in-mould labeling at that time, and special injection moulding machines were required. In 2009, the EU member state Part of the ban on the import of melamine tableware has led to the rapid development of PP-made in-mould tableware and made in-mould products truly integrated into people's lives.

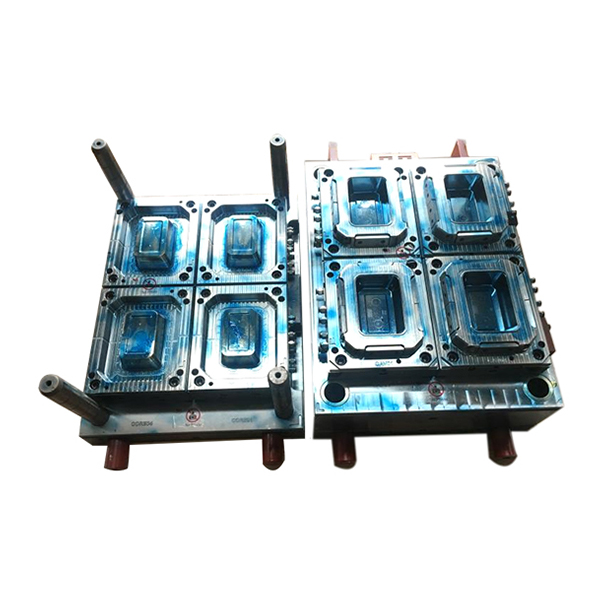

Mould name:

IML Dinner Plate Mould

Product size:

300ml-2000ml

Number of cavities:

1 cavity

Die steel material:

P20/718H/NAK80/S136H

Mould size:

300ml-2000ml

Suitable for injection moulding machine:

250T

Hot runner:

YUDO/HASCO/Master

Ejection system:

Push plate ejection

Mould cycle time:

15S

Mould life:

3 million

Mould lead time:

40-65 days

Mould characteristics:

1. IML dinner plate mould core cavity S136 steel material, which helps to enhance the life of the mould.

2. The design method of plastic parts for depressurization and drainage reduces the clamping force and gram weight.

3. Excellent cooling and exhaust system to meet the requirements of high-speed injection moulding process.

4. Excellent mould structure and precise processing technology ensure dimensional tolerance and achieve uniform wall thickness of the product.

About us

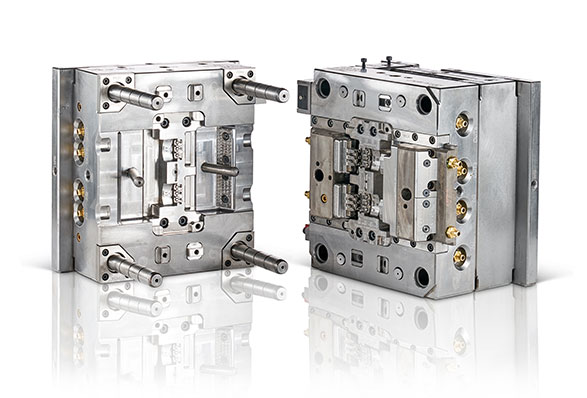

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM IML Dinner Plate Mould etc.

Kelong Mould is a famous China IML Dinner Plate Mould suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology IML Dinner Plate Mould maker.

READ MORE

Serving the world famous

brand mold supplier

Pre-sale service

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

Training and learning

If necessary, we can send engineers to debug,

or you can arrange person to train in Kelong to learn mold debugging and maintenance.

In-sale service

We will perform a mold flow analysis for each mold and provide the analysis report to the customer. When each part is processed, we will conduct quality inspection to ensure that each part is qualified.

After-sale service

1. 1-year warranty .

2. The die life of Kelong is more than 500,000 steps .

3. Kelong provides life-long technical services.