We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Follow us:

Please scan the code

Advanced internal parting surface technology is usually adopted in the design of Auto bumper mould. The advantage is that the parting line is hidden on the non-appearance surface of the bumper, and the parting line cannot be seen after being assembled on the car, which will not affect the appearance of the product. However, the difficulty and structure of this technology are more complicated than that of the outer parting type bumper, and the technical risk is also higher. The cost and price of the Auto bumper mould will also be much higher than that of the outer parting type bumper. It is widely used in high-end cars.

Most car bumpers have large-area undercut structures on both sides, which can be either external or internal. The choice of these two types of parts mainly depends on the requirements of the end customer's auto OEM for Auto bumper mould. Generally, most European and American cars use internal parting technology, and most Japanese and Korean cars use external parting.

The two parting methods have their own advantages and disadvantages. The external parting bumper needs to deal with the clamping line, which increases the processing process, but the mould cost and technical difficulty of the external parting bumper are lower than that of the internal parting bumper. The inner parted bumper is perfectly injection-moulded at one time through the secondary track change track control technology, thus ensuring the appearance quality of the bumper and saving the processing procedures and processing costs of plastic parts. But the disadvantage is that the cost of Auto bumper mould is high and the technical requirements are high.

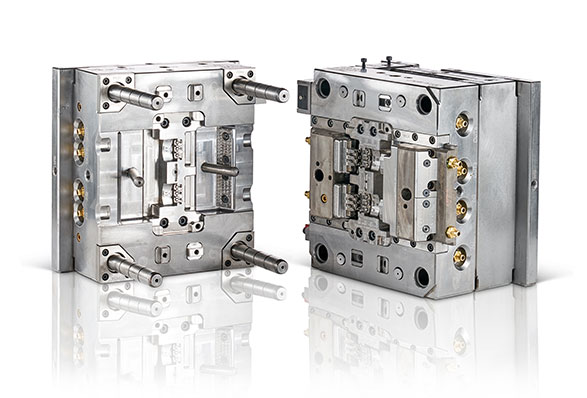

Taizhou Kelong Plastic Mould Co., Ltd. is located in Huangyan, Taizhou, China, known as China Mould Kingdom, specializing in manufacturing plastic moulds, plastic products, home appliance moulds, daily necessities moulds, industrial moulds, custom OEM Car Bumper Mould etc.

Kelong Mould is a famous China Car Bumper Mould suppliers, specializing in largae and complex injection moulds,

World-renowned brand of high technology Car Bumper Mould maker.

Kelong provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible.

If necessary, we can send engineers to debug, or you can arrange person to train in Kelong to learn mold debugging and maintenance.

We will perform

1. 1-year warranty . 2. The die life of Kelong is more than 500,000 steps . 3. Kelong provides life-long technical services.

We strive to develop our R&D capabilities and Manufacture and provide more cost-effective products to meet your market needs.

Please scan the code