Plastic basins are a common household item that serves various purposes, from washing dishes to cleaning vegetables. These versatile and functional products come in different shapes, sizes, and designs to suit different needs.

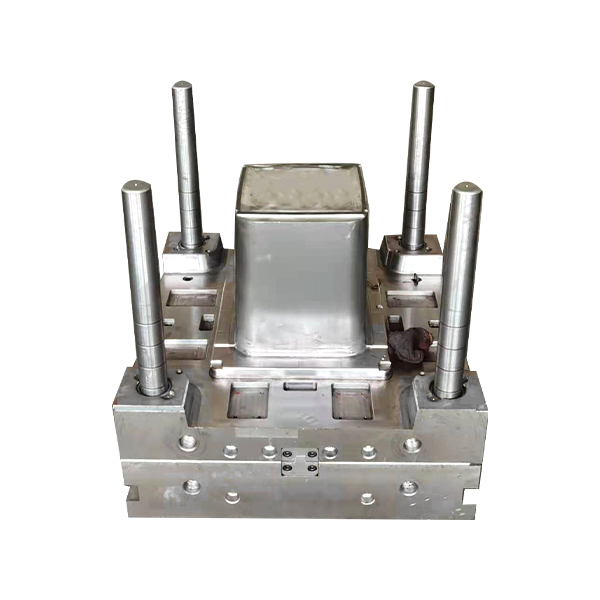

The first step in creating a plastic basin is designing the mould. The design process involves taking into consideration the desired shape, size, and features of the basin. The designer must also take into account factors such as the type of plastic to be used, the production method, and any specific requirements of the client or market.

Once the design is finalized, the next step is the creation of the mould. Plastic basin moulds are typically made from high-quality steel or aluminum. These materials are chosen for their durability and ability to withstand high temperatures and pressures without warping or deforming. The plastic basin mouldis created by machining or milling the steel or aluminum material into the desired shape. Precision is crucial during this process to ensure that the plastic basin mould accurately reflects the design specifications.

Once the plastic basin mould is created, it is time to start the production process. The plastic material, in the form of pellets or granules, is heated and melted to a liquid state. The liquid plastic is then injected into the plastic basin mould at high pressure and cooled rapidly to solidify it. This injection molding process allows for the creation of intricate details and precise shapes, ensuring that the finished basin meets the desired functionality and elegance.

Craftsmanship plays a vital role in creating plastic basins that not only serve their purpose but also add aesthetic value to the user's space. Skilled craftsmen carefully monitor the injection molding process, ensuring that the plastic material is evenly distributed in the plastic basin mould and that there are no defects or deformities in the final product. They also pay attention to details such as the smoothness of the basin's surface, the strength of its handles, and the overall balance and stability of the design.

In addition to functionality and elegance, plastic basin molds also contribute to sustainability efforts. Many manufacturers use recycled plastic materials in the production of basins, reducing the amount of waste generated and conserving valuable resources. Moreover, plastic basins are lightweight and durable, making them energy-efficient in terms of transportation and reducing the need for frequent replacements.

The journey of plastic basin moulds does not end with the production of the first batch. plastic basin mould maintenance and upkeep are essential to ensure the longevity of the plastic basin mould and the quality of the basins produced. Regular cleaning and inspection are conducted to remove any residue or debris that may affect the plastic basin mould's performance. If any repairs or modifications are necessary, skilled technicians handle them promptly to minimize downtime and maintain production efficiency.

In conclusion, plastic basin mould makers are the unsung heroes behind the creation of functional and elegant household products. These molds are carefully designed and crafted to meet the specific requirements of the basin, encompassing factors such as shape, size, and features. Skilled craftsmen play a crucial role in ensuring the quality and aesthetics of the final product. Moreover, plastic basin moulds contribute to sustainability efforts through the use of recycled materials and by producing lightweight and durable basins. So, the next time you use a plastic basin, take a moment to appreciate the craftsmanship and journey that went into creating such a practical and beautiful item."

English

English Español

Español

.jpg)

.jpg)