General mold making includes

mold design, material selection, heat treatment, machining, commissioning and installation processes. According to the survey, the material used and the heat treatment are the main factors affecting the service life of the mold. From a Total Quality Management (TQM) perspective, the factors that affect mold life should not be measured as the sum of polynomials, but as the product of multiple factors. In this way, the advantages and disadvantages of mold materials and heat treatment are particularly important in the entire mold manufacturing process.

From the analysis of common phenomena of mold failure, plastic molds will have wear failure, local deformation failure and fracture failure during use. The important damage methods of plastic molds can be divided into wear damage, local plastic deformation damage and fracture damage.

The performance requirements of plastic mold steel With the rapid development of the manufacturing industry, plastic molds are an indispensable tool in plastic molding processing, and the proportion and proportion of mold production increase year by year. With the development of high-performance plastics and continuous production , There are more and more types of plastic products, and their uses are constantly expanding. The products are developed to electric motors, which are large and complex. With the rapid development of molding production, the working conditions of molds are becoming more and more complicated.

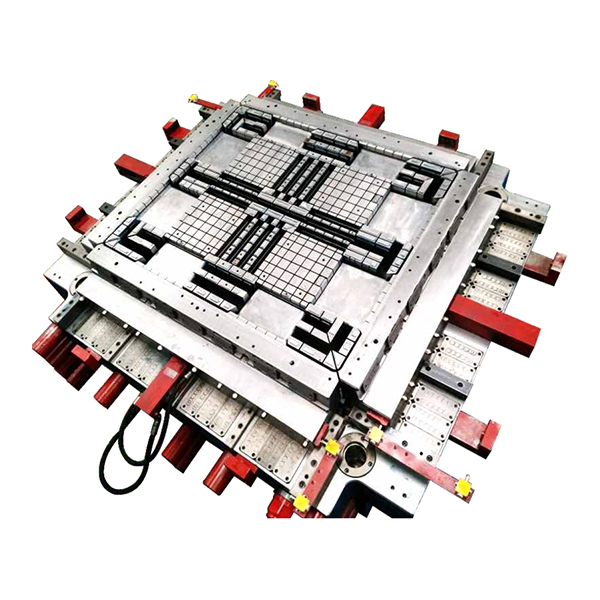

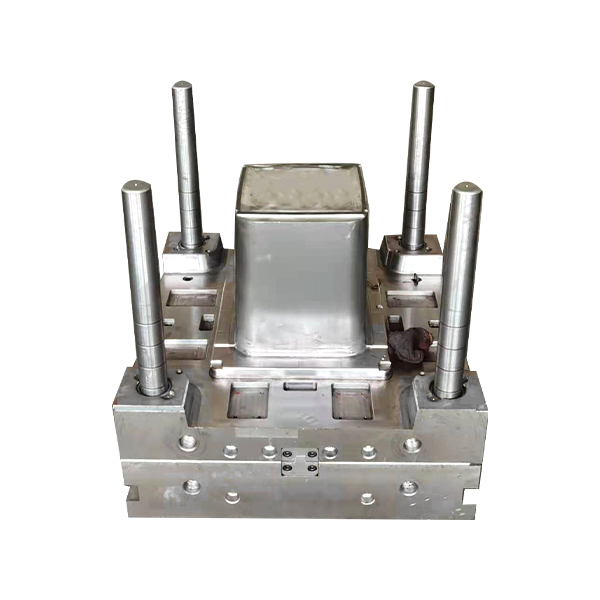

Logistics Nine-Leg Pallet Mould

Choose different materials for the role of different pallet mould structures, and use scientific and reasonable materials for the mould base, mould core cavity and slider part. Our company adopts 3 times of treatment in the mould steel, quenching and tempering, vacuum quenching 50-52 degrees hardness, and the third temperature is tempered for 48 hours.

English

English Español

Español

.jpg)

.jpg)