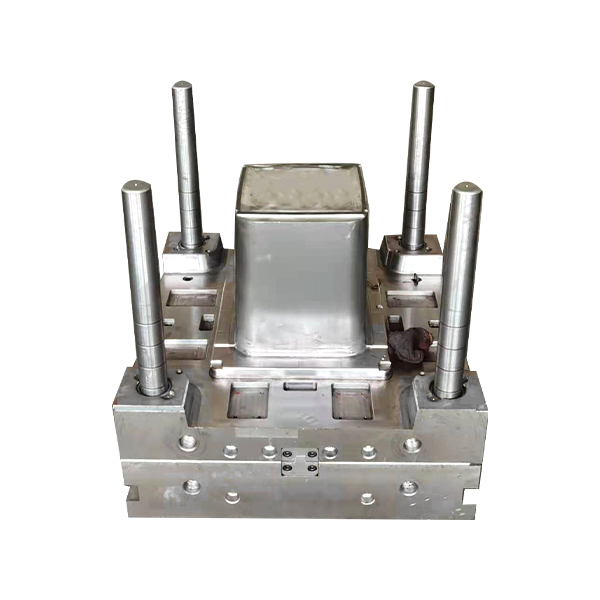

With the continuous development of science and technology, Industrial mould is increasingly used in various fields. From food packaging to electronic products, from agricultural coverings to building materials, industrial mould have become an indispensable part of modern industrial production because of their lightness, durability, and strong plasticity. However, in the production process of industrial mould, the application and optimization of circulating water systems are of great significance for improving production efficiency, reducing energy consumption, and reducing environmental pollution.

In the production process of industrial mould, the cooling system is a crucial link. The circulating water system continuously delivers water to molds, extruders and other equipment to cool high-temperature plastics and solidify them. Through the application of circulating water system, the energy consumption in the production process can be effectively reduced, the cooling efficiency can be improved, and the production speed of industrial mould can be increased.

In the industrial mould production process, the cleaning system also requires the support of circulating water. The circulating water system can collect, process and reuse the wastewater generated during the cleaning process, reducing the waste of water resources. In addition, the circulating water system can also effectively remove impurities and residues on the surface of industrial mould and improve product quality.

In the industrial mould production process, the heat recovery system can effectively use circulating water to recover and reuse waste heat. Through the circulating water system, waste heat can be transferred to other production links, such as heating, drying, etc., thereby reducing energy consumption and improving energy utilization.

The circulating water pump is the core equipment of the circulating water system, and its performance directly affects the operating efficiency of the circulating water system. In order to improve the efficiency of the circulating water system, high-efficiency and energy-saving circulating water pumps can be used, such as variable frequency speed pumps, non-clogging pumps, etc. By optimizing the performance of the circulating water pump, energy consumption can be reduced and the operating efficiency of the circulating water system can be improved.

During the operation of the circulating water system, a large amount of wastewater will be produced. In order to reduce the waste of water resources, advanced water treatment technologies, such as reverse osmosis, ultrafiltration, ion exchange, etc., can be used to treat and reuse wastewater. By optimizing water treatment technology, the water resource utilization rate of the circulating water system can be improved and production costs can be reduced.

In order to ensure the normal operation of the circulating water system, the system needs to be monitored and maintained in real time. By installing sensors, controllers and other equipment, the operating status of the circulating water system, such as water temperature, water pressure, flow rate, etc., can be monitored in real time. Once an abnormality is discovered, it can be dealt with in time to avoid any impact on industrial plastic film production.

In order to further improve the energy-saving effect of the circulating water system, energy-saving modifications can be carried out on the system. For example, renewable energy such as solar energy and waste heat can be used to power the circulating water system; new energy-saving materials, such as nanomaterials, graphene, etc., can be used to improve the heat conduction efficiency of the circulating water system; intelligent control systems can also be used to achieve the goal of circulating water. Automatic adjustment and optimization of the system.

The application and optimization of circulating water systems in industrial mould are of great significance for improving production efficiency, reducing energy consumption, and reducing environmental pollution. By optimizing the circulating water pump, water treatment technology, system monitoring and maintenance, etc., the operating efficiency of the circulating water system can be effectively improved and the energy consumption in the industrial mould process can be reduced. At the same time, through energy-saving transformation and the utilization of renewable energy, the energy-saving effect of the circulating water system can be further improved, contributing to the sustainable development of industrial mould production.

English

English Español

Español

.jpg)

.jpg)